The ability to sand veneered panels without damage

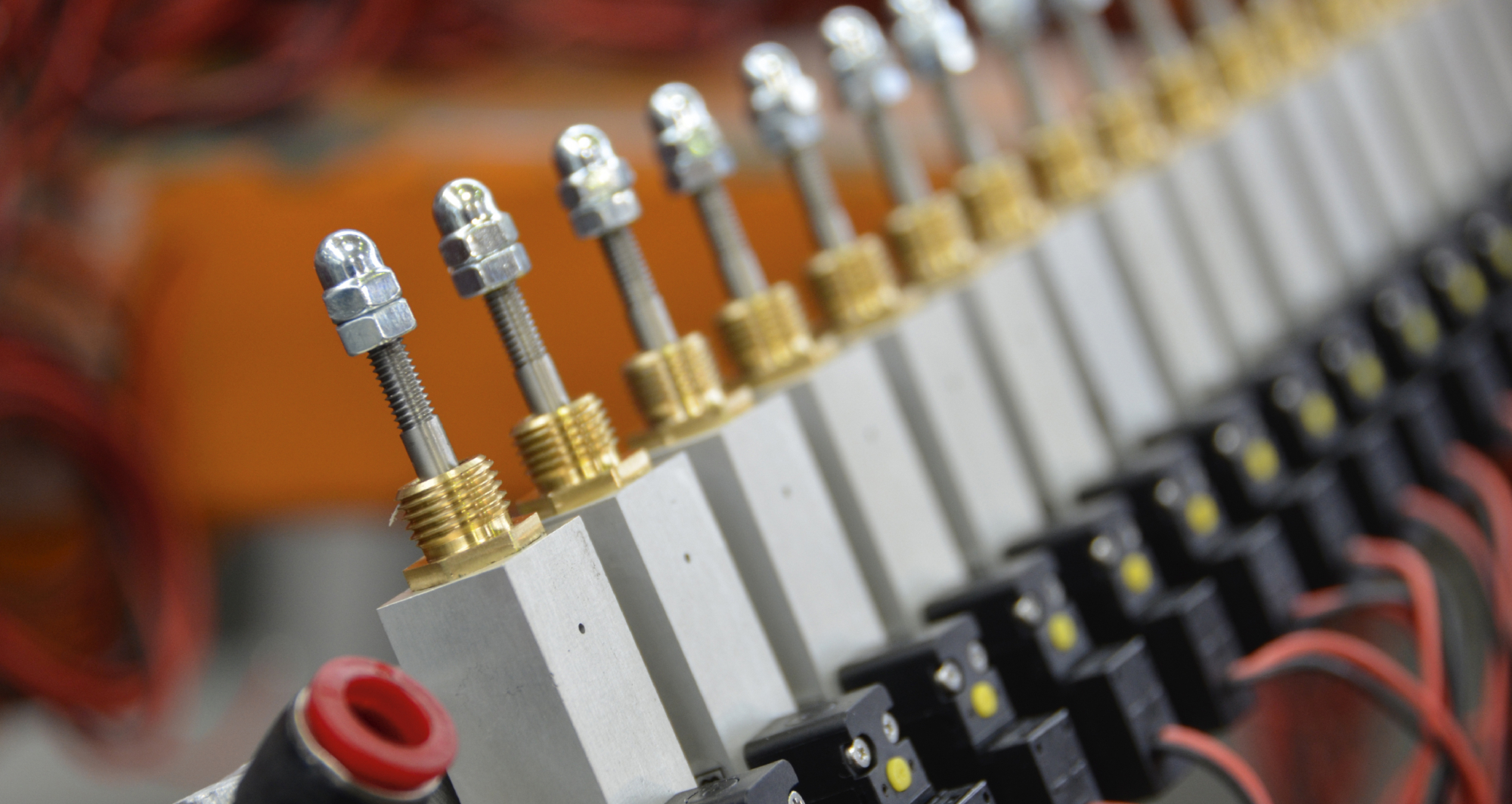

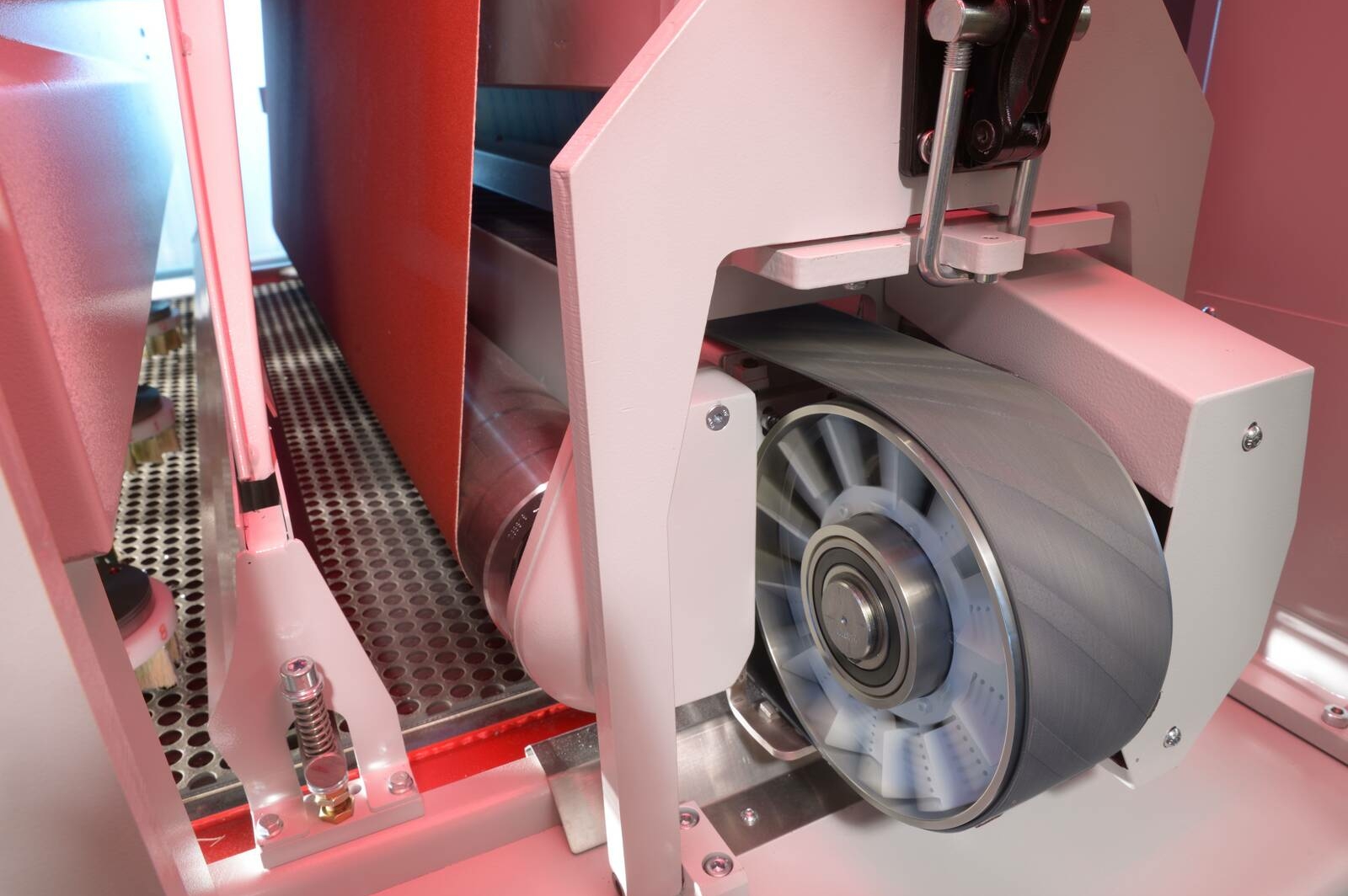

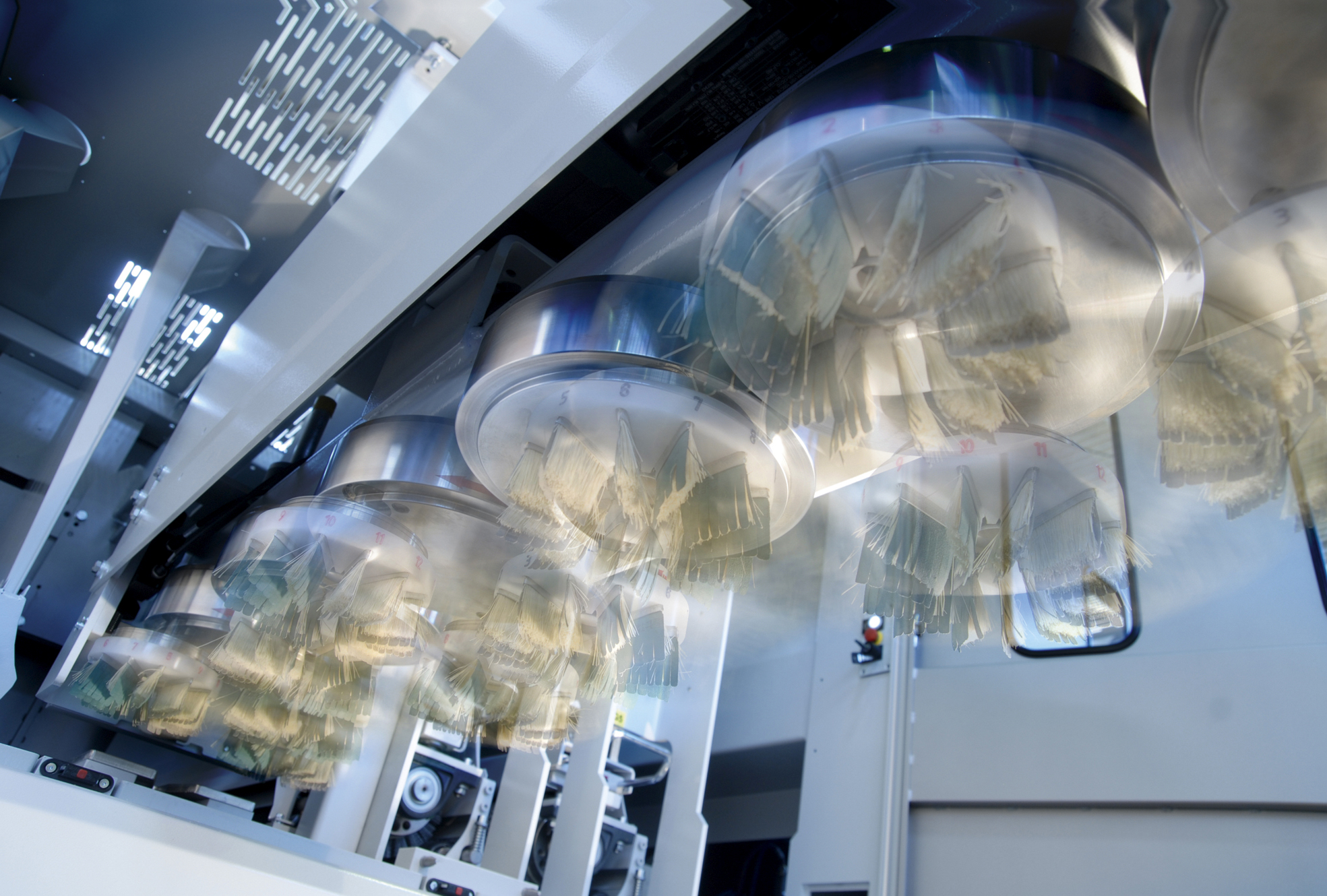

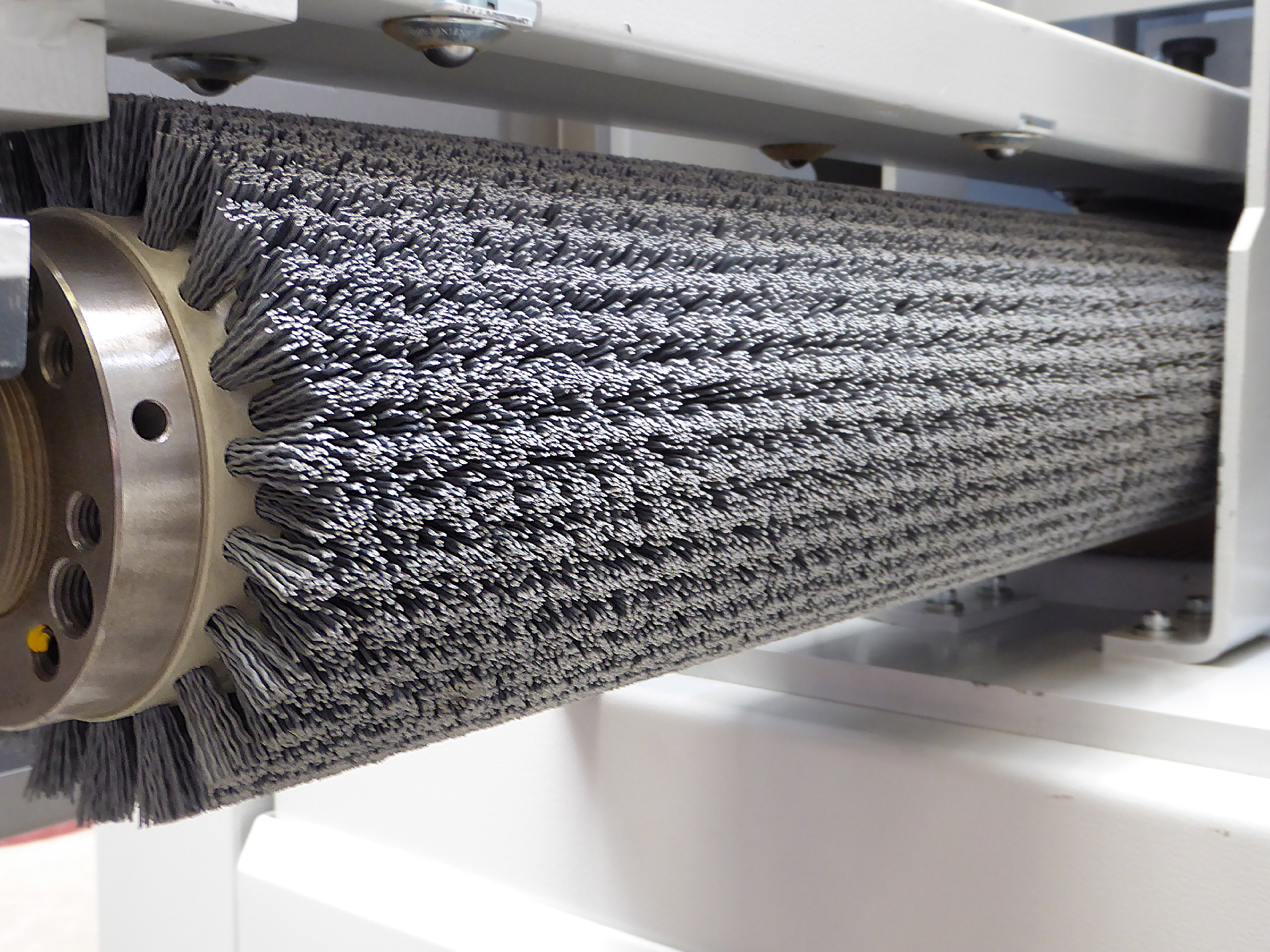

„I have a cabinet shop in Southern California. I was in the market for a new sander and have had a few widebelt models in the past. The main reason that I was upgrading was that I needed a machine with 53” width and the ability to sand veneered panels without damage. I had previously owned a double head 43” sander with air platen and did not trust the machine when sanding veneered panels. It was always a job for hand sanding, which is expensive and time consuming.The WEBER sander has a few features that make sanding difficult parts a breeze. First of all the machine has a segmented platen which uses 22 mm air cylinders to control the pressure of the platen. […] The machine with variable speed on both the sanding heads and the conveyor belt is setup for lacquer sanding. The belt speed is slowed down, and the feed is sped up. With the CBF head the machine does very short sanding strokes, which does not load up the paper. The automatic belt cleaning during this program cleans the sandpaper. What happens is almost magical and the results are stunning.

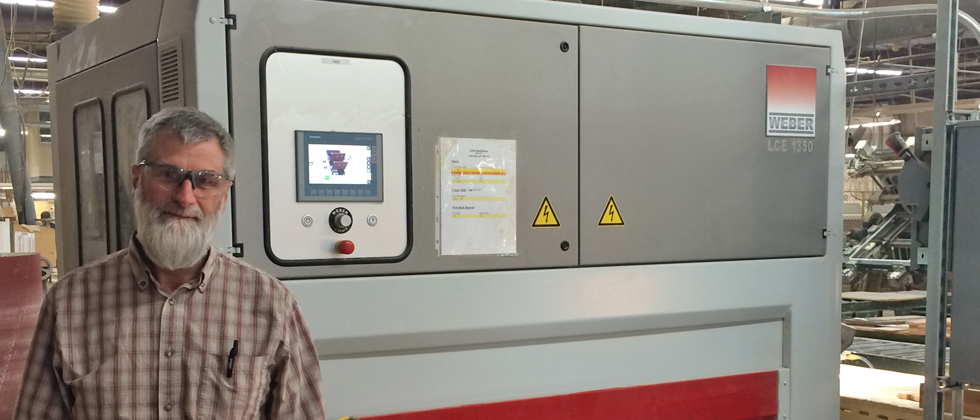

The build quality of the WEBER is first class. The machine is made almost 100% at their factory in Bavaria Germany. WEBER makes metal sanding machines that are workhorses and uses this same heavy-duty construction in the wood line. The electronic parts are either Siemens or Toshiba and can be sourced overnight if the machine needs repairs (so far no issues with my sander).

I could not be happier with my purchase. I have had 2 other German sanders and neither one compares with the WEBER.“

Scott Slater

Bespoken Woodworks

Sierra Madre, CA